usbtiny-ir-lcd-switch

Atmel has a neat microcontroller series called

AVR, which is especially suited to

use for hobby projects due to pricing, availability, ease of use and

reprogramming (all have flash), and open source toolchains (which I'm working on

for openSUSE).

For this microcontroller Dick Streefland

has created a software based USB protocol implementation called

usbtiny, including an application

to receive IR remote signals with an igorplug-usb compatible protocol.

I have stripped down the code so that I was able to add detection of a single

programmable IR signal. When the signal is detected, an output pin triggers a

power button press for 250ms. That way e.g. media center PCs can be switched on

remotely. The current state of the project is

available for

download, the git repository is probably following soon. I suggest using

gcc 4.3.3 for cross compiling (available for Debian, or from the

openSUSE project),

because the code is pretty fragile on compiler changes due to manually coded

preambles. usbtiny version 1.5 should improve that (see below).

|

|

Two python scripts are included, one for reading raw ir values and checking for

minimum/maximum intervals (train.pl) and one for programming those values

(prog_switch.py). The latter takes a raw layout, there is a script to reformat

and "soften" the values (do_prog_eeprom_ffwd.sh) - all of which isn't really

polished yet. I would rather include the reformating in prog_switch.py, but my

Python isn't really good enough for that without major pain (and I couldn't get

the Perl libusb bindings running).

My changes were based on version 1.4 of Dick's project, however, in the

meantime Dick released version 1.5. These changes have not been incorporated

yet.

Also, Dick and I currently disagree on the maximum number of cycles that

interrupts may be disabled - and it's not completely clear who is missing what

in the calculations :-) Currently I stick with my more conservative numbers. An

excerpt of the discussion can be found here,

so please comment if you think you have found a solution for us.

The current implementation just barly fits into an AVR Tiny 2313 (which has

2048 bytes flash, 128 bytes RAM, and 128 bytes EEPROM) when all features are

enabled: it uses 2044 bytes Flash, 123 bytes RAM, 70 bytes EEPROM... Pretty

dense, eh?

|

|

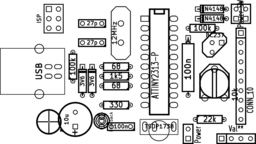

During this project I decided to revive my passing knowledge about board

layouting and etching. For layouting I have used

kicad, IMHO the first open source

layouting software that is actually usable, so I don't have to use proprietory

software like Eagle (which is pretty ok by itself). I'm using the classical

approach, printing to film via a

color laser printer (they have higher toner coverage than b&w printers),

exposing boards with light-sensitive resist to UV-A, and finally etching the

result with half-concentrated hydrochloric acid and little(!) concentrated

hydrogen peroxide. I won't give details here, because the resulting acid mix

may be harmful (even producing chloric gas if not handled right) and should be

left to people that have at least a little understanding how the chemicals

might react. Google for it if you think you're fluent enough in inorganic

chemistry.

The result looks pretty good, the 8/10 mil raster shows excellent sharpness and

only very little undercut. Especially considering that the material and

chemicals have been laying around here unused for - what? - 20 years...

There's only a small gap in one of the

circuit paths, looking like the base material had been damaged (the film is

100% ok in this region). Anyway, the resulting board is working just fine when

this gap is closed :-)